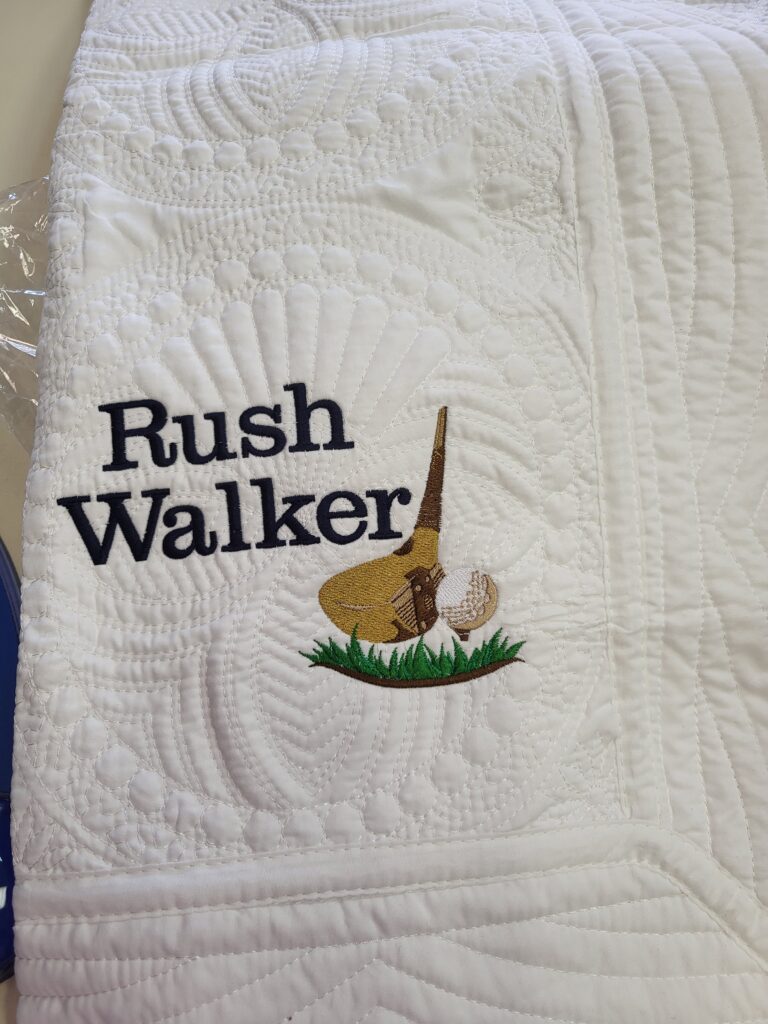

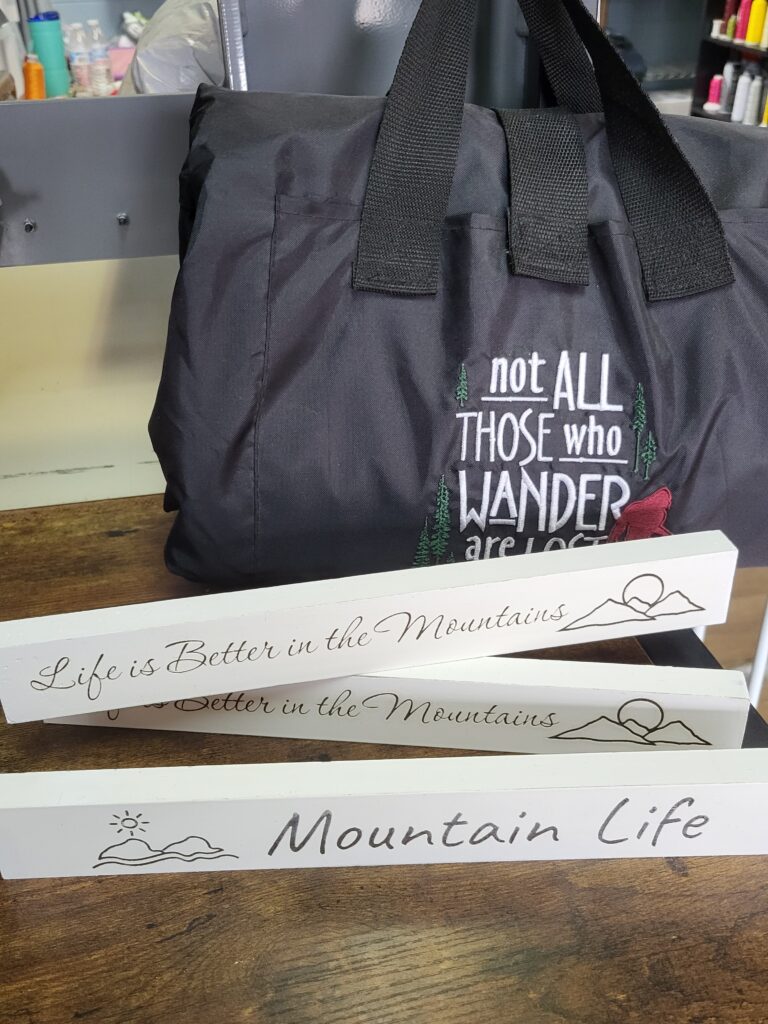

If you can imagine it, we can probably print it!

You may already know that we are Ellijay’s leading embroidery shop, but did you know that we also custom print t-shirts, hats and just about anything else that you can imagine? We have all of the major brands and styles!

The 4 main types of apparel printing are DTG (Direct to Garment), DTF (Direct to Film), Screen Printing and Dye Sublimation. When it comes to deciding which type of apparel printing is right for your business or the project at hand, consider the following factors:

Ideas From Our Catalog

How to Choose the Best T-Shirt Material

There are a lot of factors that people consider when it comes to t-shirt fabric. Each fabric has its various pros and cons, and no hard evidence seems to show that one is better than the other – you just have to make sure that you choose the right one for you. The fabric plays a big part in not only the design and printing, but in the way it feels and the way it’s worn. Some t-shirt fabrics hold ink better than others, and some fabrics are longer lasting. If you know the difference between the fabrics, you’re going to make a better decision.

Cotton

Cotton is the most common type of fabric that is used to make t-shirts. This is because it is soft and breathable and strikes a perfect balance between cost and comfort. The main drawback to cotton is that it wrinkles and it often shrinks in the laundry. There are a few different types of cotton that can be used for shirt production:

Types of Cotton:

- Combed cotton is created when short strands are eliminated, then fine brushes straighten the fibers. This makes the fabric softer, smoother, and stronger. It also makes for a better material for printing. Combed cotton is made from pretreated fibers that produce a softer, more durable fabric.

- Organic cotton is more expensive than regular cotton, and the cotton is grown without many fertilizers or pesticides. If environmental impact and sustainability are important to your brand, organic cotton is the way to go. It utilizes the most popular t-shirt material but limits the selection to materials that achieve certain standards for limiting their impact on the environment. This type of cotton is more labor-intensive to produce and therefore more expensive to buy.

- Pima cotton is known to be the highest quality cotton that money can buy, with extra long fibers which ensure the softness of the t-shirt fabric. Pima cotton is durable – it resists pilling, fading, and stretching. Supima is the same type of cotton as Pima, but it’s specifically grown in the US.

- Slub cotton is a type of cotton that looks like it has slight lumps in the fabric. This is created before the cotton is weaved, where the cotton is twisted, and the twists are irregular. Slub cotton is unique – it’s light, airy and does not cling to the body. It’s also naturally textured, which means that there is no need to iron it.

Linen

There are a lot of t-shirts that are made with linen. It comes from the flax plant, and the weave is textured. It’s such a popular choice for summer clothing because of its breathability and lightweight properties. Linen is also moisture-wicking and dries quickly. Although it’s a great summer material, it can easily wrinkle.

Polyester

Another common fabric used for t-shirts is Polyester. It’s quick drying and doesn’t mildew. It also maintains its shape without stretching. Most athletic apparel companies use polyester in their t-shirts. Polyester is synthetic and includes fabrics like nylon, acetate, and acrylic.

Polyester is durable, drying fast after a wash. It’s also flexible, cost effective, can potentially be recycled, and can blend with cotton. Along with these positive attributes, there are some drawbacks. Polyester doesn’t break down quickly, doesn’t breathe easily, and it can release plastic microfibers when it’s being washed, which in turn causes water pollution.

Rayon

Rayon is another athletic-wear fiber, and it’s been created as an affordable alternative to silk. Rayon is a human-made fiber formed from trees, plants, and cotton. What you get in the end is a breathable fabric that feels silky and drapes effortlessly. It dyes well, and it’s absorbent. However, it wrinkles easily and is not known as the most eco-conscious option.

Lycra

Lycra is the best-known name, but really it’s Spandex which is an additive to other t shirt materials. It’s used to give t-shirts more room to stretch, and it’s found in athletic wear more than anything else because of the ease of movement.

Cotton/Polyester Blend

The best of both worlds is a blend between cotton and polyester. Not all blends are created equal, so you will need to look at the percentage of each material in the blend before making a decision. However, most cotton/polyester blends are soft like cotton and wrinkle-resistant like polyester.

Tri-Blends

T-shirt manufacturers have found another way to improve on a good thing! By adding rayon to the mix, they have created an ideal t-shirt blend that marries the comfort of cotton and the durability of polyester with a touch more softness and lighter weight with rayon.

Understanding T-Shirt Weights

What goes into making a comfortable t-shirt? What specific qualities should you look for when choosing t-shirts for your brand? For one, the weight of the material. Heavier weight t-shirts that are more than 6 oz are better suited for colder climates. If you are an outdoor brand popular in mountainous regions, this will be more important for you. Lightweight t-shirts typically range between 3 – 5 oz and are more comfortable for warmer weather.

Lightweight t-shirts tend to have a more fashionable fit, whereas heavier t-shirts have a more utilitarian fit. The average t-shirt weight is somewhere between 4.5 oz and 6 oz. Weight below this range is comparatively not as durable. In some instances, however, a lightweight t-shirt material is appropriate, for example, shirts that might serve as a novelty item for one-time use, such as for an event.

T-Shirt Weights

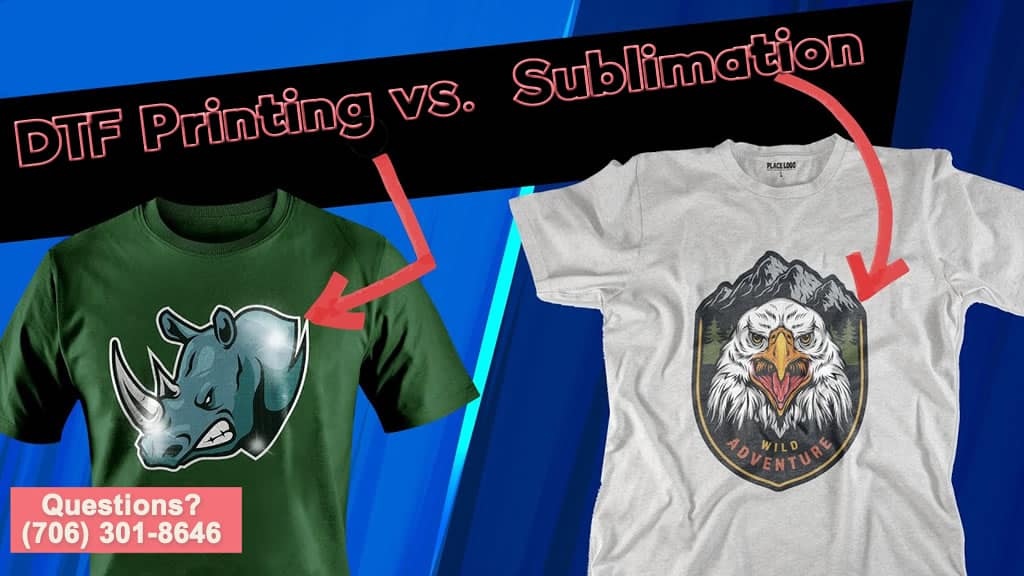

DTF Printing

DTF solves a lot of problems of other printing methods while producing great results and most importantly being affordable. DTF will allow you to print on 100% cotton and black garments, it will also have great feel and washability. We will be able to print on demand quickly and conveniently, without having to worry about production delays.

Direct to film, or film to garment printing, involves printing the image onto a film first, then transferring the image from the film to the fabric. DTF printing does not require any pretreatment of the fabric, but it does require a powder to be applied after the image is transferred onto the film to prevent the ink from running or streaking.

What is Dye Sublimation?

Sublimation printing is a unique type of printing different from DTG and DTF, two other printing processes. In sublimation printing, an image or design is transferred to the paper and then transferred to the fabric through a heat-transfer process.

Dye Sublimation printing allows for incredibly smooth tones and is the best option for photography designs. There is simply no better method for creating realistic results. In this printing method, the ink is fused with the fabric rather than sitting on top. This ensures that the design will last through hundreds of washes without fading.

Sublimation printing uses a unique process that is different from DTG and DTF. Instead of liquid ink being printed onto fabric or film, a solid ink substance transitions from a solid state directly to a gas without ever becoming a liquid. The image is printed onto transfer paper and then transferred to the fabric. The ink is heated until it blends right into the fibers of the fabric.

You can only use this printing method to print on polyester and polymer-coated substrates. If you prefer hats and t-shirts made from natural fibers like cotton, this method might not be suitable for you.

What is DTG printing?

Direct to garment printing works just the way the name suggests: the printer prints the image directly onto the fabric. There is no film or transfer paper required, however, the garment does need to be pretreated to ensure that the image transfers properly. DTG printing requires a specific type of ink and is usually best when printed on cotton fabric.

DTG printing is generally more suitable for one-offs or small quantities of printing. This makes it a popular choice for small rush-jobs. DTG printing is great for detailed designs and many colors. It is also a good way to render photographs onto any garment. That said, it is not ideal for images that are dark or opaque.

What is Screen Printing?

Screen printing, also known as silkscreen printing or simply silk screening, is an analog or pre-digital technique that’s been used for decades. With this process, plastisol-based inks are pressed through a screen onto a garment such as t-shirts, sweatshirt, baseball cap, or another items.

Different screens are used for different colors. The screens are attached to a press, which rotates and allows the designs to be imprinted on the garments. Even though screen printing is an analog process, when you place an order for printing, you’ll generally send files that contain the design in a format such as EPS to the printing company.